Background knowledge

In the rapid development of the automobile industry, the quality detection of spare parts is crucial. As an important part of the engine pressurization system, the performance and quality of intercooler directly affect the efficiency and reliability of the engine.

The application of 3D wire laser camera technology provides a high precision, high efficiency, comprehensive and non-contact detection method for the detection of intercooler. It can not only improve the detection accuracy and efficiency of the intercooler, but also ensure the quality and reliability of the intercooler, providing strong support for the development of the automobile industry.

Camera selection

Today for you to introduce the application of LVM2530 line laser 3D camera in the automotive industry detection!

The LVM2530-line laser 3D camera is an ultra-high-speed 3D intelligent sensor; can provide 2500Hz full frame acquisition rate, physical contour 1920 points, depth spacing sampling 4096 points; LVM2530 Z repetition precision to 0.6 μ m, the proximal field range (FOV) is 55.4mm, the distal view range (FOV) provides the best target for 90.5mm, is the ideal choice for high-speed online detection system.

surveillance project

Workpiece information

·Size: 110mm * 70mm

·Material: aluminum alloy

·Color: silver white

Test requirements

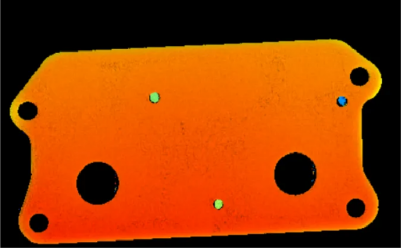

·Test requirements: flatness

·Accuracy requirement: 0.2mm sealed area (shaded area) and 0.3mm unsealed area

*as shown in the figure

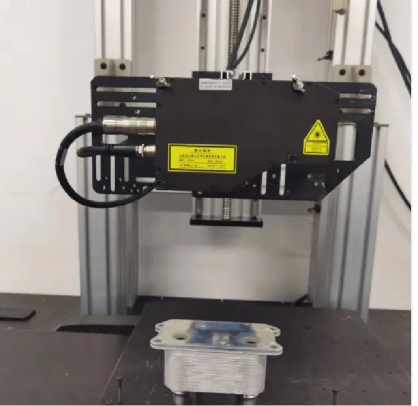

Detection environment and installation method

·Environment Description: After the camera is fixed, the product scans along the center straight line movement

·Acquisition trigger mode: Encoder trigger

·Communication: TCP / IP

Drawing effect

measured data

Test conclusion

·Customer requirements: planness detection effect is clear, the maximum repetitive data is: 0.006<0.2mm, to meet customer needs

·Test value: it can significantly improve product quality and reduce production costs

2024/09/20

2024/09/20