一. background knowledge

Many pharmaceutical production lines have applied machine vision methods to the granulation and automated packaging of tablets.

The traditional manual detection method is labor-intensive, the human eye is easily fatigued, the efficiency is low, and it is prone to false detection and missed detection.

Machine vision inspection has the characteristics of high efficiency, high precision and strong real-time performance, and meets the requirements of high inspection pass rate and high-efficiency operation that are necessary in the manufacture of tablet granules.

At present, the domestic tablet particle detection is mainly based on the 2D visual detection scheme. The standard inspection process is on the assembly line. When the inspected product reaches the designated position, the trigger component is activated, and one or more high-speed 2D cameras start shooting. The designed auxiliary light source is turned on during the whole process to ensure the image quality. Examples of foreign high-speed pellet production equipment are as follows:

(High-speed tablet granule production equipment)

For tablet detection based on 2D images, the current algorithm is relatively mature, and the difficulty lies in obtaining high-quality images at high speed. Because the surface of the tablet is curved, the equipment using the 2D camera combination needs to have uniform illumination in the entire field of view to detect dirt and defects on the surface of the tablet. However , it is difficult for the light source to be completely uniform for highly reflective surfaces. Therefore , due to the influence of surface gloss and curvature, it is difficult to stably perform appearance inspections such as damage to blister packaging.

Using the 3D vision system, the influence of the surface condition can be excluded, and the defect can be accurately detected. The machine vision inspection solution based on the integrated high-speed and high-precision 3D line laser camera LVM-2630 launched by Yishi Technology for this application scenario can meet the requirements for the production of tablet granules, granule blister packaging, and the integrity of the back of blister packaging in the pharmaceutical industry. Detection needs.

二. Detection scheme

The integrated 3D camera (LVM-2630) 3D scanning system solution of Nextvision Technology cooperates with the detection system software, which can scan all the coordinate data of the tablet particle board very quickly. x Detection of blister defects.

2.1 Using the camera

All-in-one 3D line laser camera LVM-2630.

The LVM-2630 has 1920 actual physical contour points in the X direction, the maximum FOV field of view width is greater than 100mm, and the Z-direction depth of field is greater than 80mm. Capture speeds up to 2500 frames per second in full frame. It is suitable for high-precision high-speed measurement of tablet granules and tablet granules blister sheets.

|

Product number |

LVM-2630 |

|

Laser wavelength |

405nm |

|

Clear installation distance (CD = D1, mm) |

62.7 |

|

Proximal FOV (W1) (unit mm) |

62 |

|

Distal FOV (W2) (unit mm) |

102 |

|

Depth of Field (MR = D2-D1, mm) |

84 |

|

contour points |

1920 |

|

Resolution in X direction (unit um) |

32 to 53 |

|

Resolution in Z direction (unit um) |

4 to 6 |

|

Z direction repeatability (unit um) |

2.5 |

|

Linearity in Z direction (+/-% of MR) |

0.02 |

|

Scan speed (point cloud profile/sec) |

2500~56000 |

(LVM-2630 parameters)

2.2 Detection method

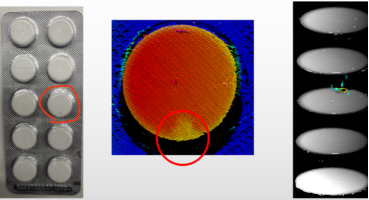

l It is beneficial to 3D point cloud data, and methods such as Blob and template matching can be used for the detection of tablet particle defects ;

l Image comparison, height difference measurement, etc. can be used for blister packaging defects ;

l The device can also directly connect to the existing 2D detection scheme, and provide image data by 3D conversion to 2D for users to use existing algorithms such as binarized edge chipping detection to detect missing grains, defects or foreign objects mixed with impurities.

2.3 Testing Equipment

l Adopt the integration method of multi-camera combination ;

l Take the detection of tablet blister board in a pharmaceutical factory as an example: two LVM-2630s are installed side by side on the rack above the equipment, and two rows of tablet board assembly lines move at high speed in the Y direction below the camera. The camera completes the high-speed scanning of the material according to the production cycle. When the defective tablet moves to the designated position, the reject device removes the defective tablet plate. Complete a high-speed scan of at least 1 meter per second.

2.4 performance

l Beat: 1m / s (covering 100mm standard tablet board, more than 400,000 tablets / hour)

l Missing corners, missing caps, chips, splintered, and broken pieces of more than 1%

l Black spots or marks not less than 0.4 mm 2

l Missing coating of not less than 0.4 mm2

l Adhesive traces not less than 0.4 mm 2

l Missing corners - missing corners of not less than 1% of the area or volume

(Pill Scan Case)

2021/07/06

2021/07/06