1. background knowledge

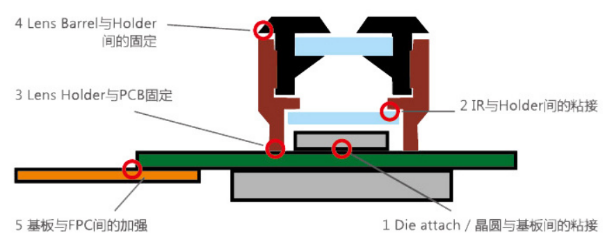

The camera module mainly includes the following parts: FPC, SENSOR, LENS, VCM, etc. Its internal structure is complex and precise, and many components need to be assembled by dispensing . In a camera module, there are as many as 8-11 processes that need to be dispensed. It can be said that the entire camera module is fixed by glue step by step.

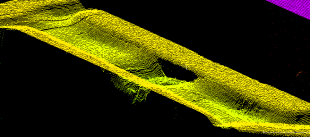

The glue point used in the camera module part is shown in the figure:

The characteristics of the dispensing process of the mobile phone camera module are as follows:

l Small components and precise components;

l The dispensing accuracy is required to be high, and the dispensing position is narrow (for example, the width of the narrow edge is less than 0.3mm);

l There are many dispensing positions;

l The glue is mostly viscous black thermosetting glue, conductive glue, solder paste, damping glue and other glue with resistance and large particles;

l Scattering, overflowing, and irregular outer diameter of the glue caused by the characteristics of the glue;

l The curing method of glue is oven curing , with various specifications , temperature 96°~128°, curing time ranging from 10min~20min .

The production line of mobile phone, a consumer electronic product, has the characteristics of fast rhythm and high testing requirements. The current 3C mobile phone industry is committed to the high-speed automation of the entire production line to achieve high efficiency and high yield of the factory production line dispensing process. Traditional manpower cannot meet the requirements of full inspection, and solutions based on machine vision are becoming more mainstream .

Taking the production process of attaching the filter after dispensing the lens base next to the camera module as an example, the dispensing width of the step on the base is only 0.4mm, and the line width of the dispensing is required to be within 0.3mm, and no glue overflow is allowed; The error of mounting the filter to the base is less than 0.05mm. Among them, manpower cannot perform online detection; 2D detection can be used for glue break detection, but it is not competent for the overflow of black colloid and insufficient glue.

2. Mobile phone camera bracket glue road detection scheme

Nextvision's integrated 3D camera (LVM-2610) 3D scanning system solution cooperates with the detection system software, which can scan all the coordinate data of the camera module very quickly, and process the camera bracket glue road through the data processing of 3D point cloud. Scanning detection, including the current single-camera, dual-three, triple-camera, quad-camera and other brands of mobile phone camera module bracket glue road defect detection.

Use a 3D camera to scan the shape of the glue road, It can realize the purpose of automatically judging whether the glue road is in good condition.

2.1 Using the camera

All-in-one 3D line laser camera LVM-2610.

The LVM-2630 has 1920 actual physical contour points in the X direction. Capture speeds up to 2500 frames per second in full frame. It is suitable for high-precision and high-speed measurement of glue drop detection of mobile phone camera module brackets.

|

LVM (Laser Vision Measurement) 2600 Series |

|

|

Product number |

LVM-2610 |

|

Laser wavelength |

405nm |

|

Installation Clear Distance (CD, mm) |

18 |

|

Proximal FOV (unit: mm) |

13.3 |

|

Distal FOV (unit mm) |

16.2 |

|

Depth of Field (MR, mm) |

7 |

|

contour points |

1920 |

|

Resolution in X direction (unit um) |

7 to 8 |

|

Z direction repeatability (unit um) |

0.5 |

|

Linearity in Z direction (+/-% of MR) |

0.02 |

|

Scan speed (point cloud profile/sec) |

2500~56000 |

|

Power (DC, V) |

+24V |

|

Laser class |

2M (adjustable output, optional 3R) |

|

Operating temperature |

0~50°C |

|

Protection class |

Aluminum alloy fully enclosed design, IP67 |

|

Communication Interface |

10 Gigabit network interface (compatible with Gigabit), 1 24VTTL input, 1 |

|

Vibration experiment |

10 to 55 Hz, double amplitude 1.5 mm, 2 hours each in X, Y, Z directions |

|

Impact test |

Half-sine shock with a peak acceleration of 15g and a duration of 11ms |

(LVM-2610 parameters)

1. Detection method

It is beneficial to 3D point cloud data to detect whether the glue road is broken and whether the glue road filling is qualified .

2. Detection effect

X and Y directions can reach below 8um. The accuracy requirements are high, and the repeatability of the testing equipment is within ±5μm. High-speed detection, the frame rate of full frame can reach 2500fps, which meets the requirements of production takt UPH1200 or more.

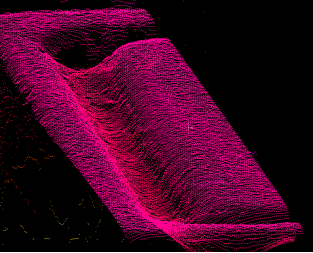

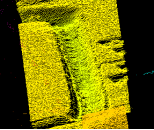

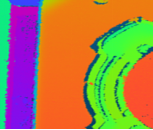

The detection and sampling effect is as follows:

parts

2021/09/22

2021/09/22