Background knowledge

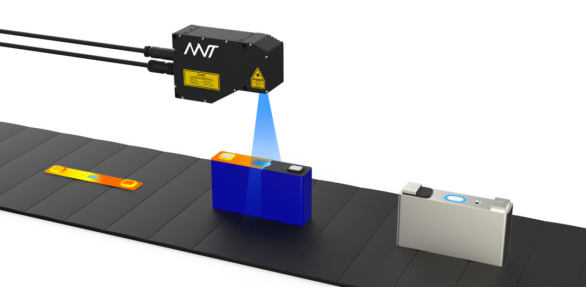

As the eyes and brain of machines, machine vision plays an important role in the development of intelligence. With the development of modern industrial automation, machine vision inspection has been widely used in various inspection, measurement and part recognition. The common characteristics of such applications are continuous mass production and high requirements for appearance quality. It can improve the production capacity of qualified products and scrap inferior products at the early stage of the production process, thus reducing waste and saving costs. The 3D camera realizes the intellectualization, modernization and automation of industrial production by capturing and analyzing the image of the product line scan and outputting the results. With the development of technology and the improvement of detection demand, the application of 3D vision will be more and more extensive.

Case sharing

1. Application of Next Vision Tech 3D camera in lithium battery industry

1.1 Inspection of welding seam on the top cover of electric core: missing welding, high welding and welding hole

Customer: global leading enterprise in the new energy lithium battery industry

Workpiece: battery cell of an internationally famous new energy vehicle

Downstream industry: new energy battery industry

Product model: LVM-2510

Technical requirements: inspect the welding quality of the top cover of the electric core (missing welding, faulty welding, bump, burst point, burst point, knife line, etc.)

Customer value: realize automatic detection; Improve product quality, prevent defective products from flowing out to the vehicle factory, and avoid serious quality accidents; Improve the consistency of test results

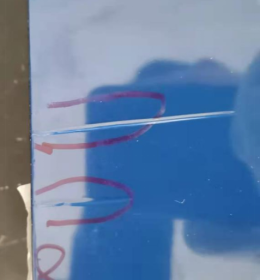

(physical picture) (point cloud picture)

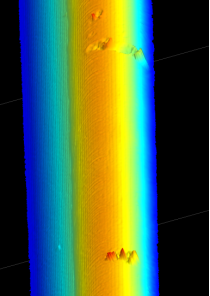

1.2 Appearance inspection of core before coating: defects such as dents and scratches

Customer: global leading enterprise in the new energy lithium battery industry

Workpiece: battery cell of an internationally famous new energy vehicle

Downstream industry: new energy battery industry

Product model: LVM-2530

Technical requirements: detect defects such as dents and scratches on the appearance of the core

Customer value: realize automatic detection; Improve product quality, prevent defective products from flowing out to the vehicle factory, and avoid serious quality accidents; Improve the consistency of test results

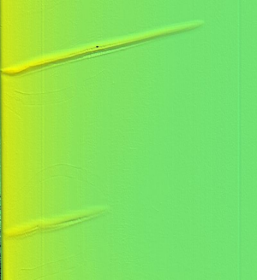

(physical picture) (point cloud picture)

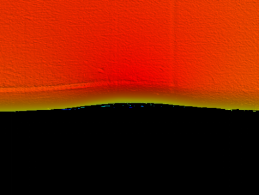

1.3 Surface defect detection of electric core after coating

Customer: global leading enterprise in the new energy lithium battery industry

Workpiece: an internationally famous new energy vehicle coated cell

Downstream industry: new energy battery industry

Product model: LVM-2530

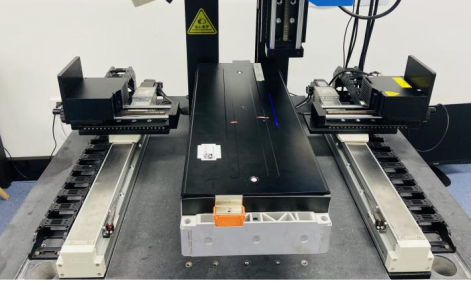

Technical requirements: two LVM2530 splices are used to detect and analyze foreign matters, scratches, wrinkles, pits, bubbles and other defects

Customer value: realize automatic detection; Improve product quality, prevent defective products from flowing out to the vehicle factory, and avoid serious quality accidents; Improve the consistency of test results

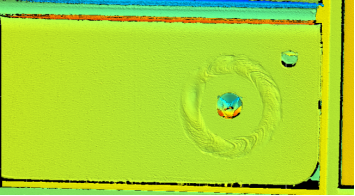

(physical picture) (point cloud picture)

1.4 Post-weld quality inspection of Busbar

Customer: global leading enterprise in the new energy lithium battery industry

Workpiece: Busbar core module

Downstream industry: new energy battery industry

Product model: LVM-2520

Technical requirements: 3D camera with 2D camera to detect the quality of Busbar after welding

Customer value: realize automatic detection; Improve product quality, prevent defective products from flowing out to the vehicle factory, and avoid serious quality accidents; Improve the consistency of test results

(physical picture) (point cloud picture)

1.5 Full-size inspection of new energy module

Customer: global leading enterprise in the new energy lithium battery industry

Workpiece: battery module of an internationally famous new energy vehicle

Downstream industry: new energy battery industry

Product model: LVM-2040, LVM-2545

Technical requirements: adopt module splicing method to detect length, width, height, flatness, segment difference, etc

Customer value: realize industrial innovative application, reduce production risk and reduce customer production loss

2、Application of Next Vision Tech 3D camera in 3C industry

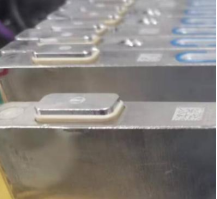

2.1 Mobile phone SIM card slot depth detection

Customer: an international well-known mobile phone parts supplier

Workpiece: mobile phone parts

Downstream industry: consumer electronics industry

Product model: LVM-2010

Technical requirements: detect the depth from the highest point of the arc on the outside surface of the mobile phone to the inner plane of the SIM slot,

Accuracy requirements: repeatability 0.01mm, detection efficiency: 3s

Solution: Z direction repetition accuracy 0.2um, X direction resolution 7-9um, field of view 15-18mm, depth of field 10mm

Customer value: It can meet customer requirements, efficiently and stably detect the depth of SIM card slot

(physical picture) (point cloud picture)

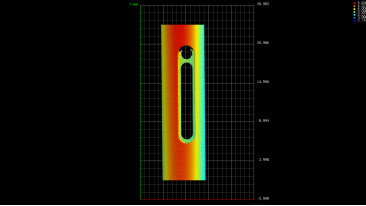

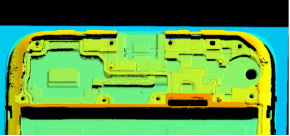

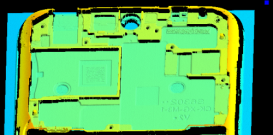

2.2 Mobile phone screw hole height detection

Customer: an international well-known mobile phone parts supplier

Workpiece: mobile phone parts

Downstream industry: consumer electronics industry

Product model: LVM-2530

Technical requirements: mobile phone screw hole height detection, accuracy requirement 0.01mm

Solution: X-direction resolution 33-54um, Z-direction resolution 2um, field of vision 62-102mm, depth of field 84mm

Customer value: efficiently and stably detect the height of screw hole of mobile phone

(Point cloud) (Point cloud)

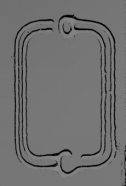

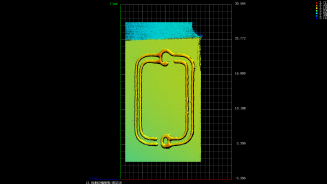

2.3 Glue height detection on the back of smart bracelet

Customer: a well-known electronic technology company

Workpiece: intelligent bracelet wearing device

Downstream industry: electronic industry

Product model: LVM-2510

Technical requirements: detect the glue on the back of the bracelet; Measure glue height

Customer value: realize 3D glue path measurement and improve product quality

(depth map) (point cloud map)

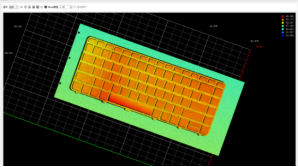

2.4 Keyboard flatness, height measurement, whether there is detection

Customer: a well-known electronic technology company

Workpiece: keyboard

Downstream industry: consumer electronics industry

Product model: LVM-2540

Technical requirements: flatness and height measurement of the whole product, and whether there is detection

Customer value: change from manual detection to automatic equipment detection, improve product quality control level and increase terminal customer satisfaction

(physical picture) (point cloud picture)

翌视科技3D相机在汽车行业的应用

3、Application of Next Vision Tech 3D camera in automobile industry

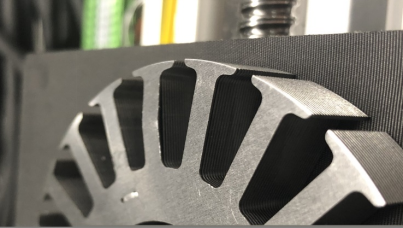

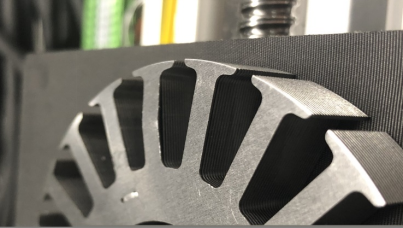

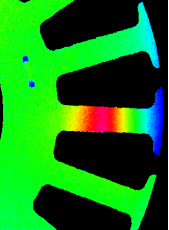

3.1 Inspection of auto parts

Customer: an automation equipment company in Shanghai

Workpieces: shaft gear components

Downstream industry: auto parts

Product model: LVM-2040

Technical requirements: sample defect detection, detection range: 100mm x 100mm, Z-direction accuracy: 0.05-0.1mm

Customer value: eliminate manual detection and realize full automatic detection

(physical picture) (point cloud picture)

3.2 Inspection of auto parts

Customer: a listed auto parts company

Downstream industry: auto parts

Product model: LVM-2540

Technical requirements: take the plastic at the bottom of the column as the datum plane to detect the depth information from the top plane of each pin to the datum plane

Customer value: eliminate manual inspection, replace coordinate spot check, realize automatic inspection, and improve product quality

(physical picture) (point cloud picture)

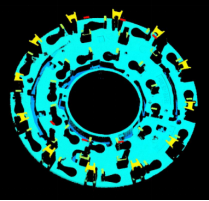

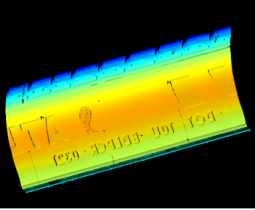

3.3 Vehicle tire detection (character recognition)

Customer: an automobile tire manufacturing company

Downstream industry: automobile industry

Product model: LVM-2040

Technical requirements: quickly generate the height map and identify the characters on the tire sidewall by scanning the tire

Customer value: eliminate manual detection, realize full-automatic detection, improve stability, improve consistency of detection results, and reduce material waste/rework

(physical picture) (point cloud picture)

2023/02/20

2023/02/20